Anti-Crak® Glass Fibers for Concrete Reinforcement

Since their development and launch in 1970, Alkali Resistant Glass Fibers manufactured by Owens Corning Composite Materials, LLC, USA, have been used in more than 120 countries for the Reinforcement of Cement and Concrete Products. They are best known for their use in factory-produced GRC elements (Glass Fiber Reinforced Concrete), but the range of Anti-Crak® glass fibers hasbeen developed to target the use of AR (Alkali Resistant) Glass Fibers in general ready-mix concrete and precast industries (e.g. flooring, thin-walled elements), pavements, screeds, renders, etc.

The state of the art facilities allow Owens Corning to provide technical support in the use of their products and design dedicated solutions for specific applications.

Owens Corning's global platform ensures support and delivery of consistent solutions in all regions.

Petroguard Canopy Systems with its head office in Mumbai and branches spread out in Bangalore, Cochin and Coimbatore is the Exclusive Distributor (Industrial Flooring segment) for a range of Anti-Crak® Alkali Resistant Glass Fibers manufactured by Owens Corning Composite Materials, LLC, U.S.A.

Why Glass Fibers in Concrete?

It is widely accepted within the concrete industry that traditional concrete mixes are prone to plastic shrinkage during the setting phase and this can often lead to cracking. The addition of relatively small amounts of fiber reinforcement can effectively reduce this problem by controlling this early-age plastic shrinkage cracking. It also avoids the need for using light steel mesh for crack control with its attendant disadvantages of handling and positioning. Fiber reinforced concrete is easy and cost effective and it also enables you to produce a hardened concrete which has:

- Improved surface quality

- Greater impact resistance

- Increased durability

Why Anti-Crak® Glass Fibers?

Anti-Crak®glassfibers are alkali resistant glass fibers, especially developed for the reinforcement of cementitious mortars and concretemixes. They can be easily introduced into a conventional concrete mixgiving millions of dispersed fibers per cubic metre of concrete, providing a highly uniform and effective reinforcement.

With its totalaffinity to cementitious composites, high tensile strength andmodulus of elasticity, glass fibers are an ideal reinforcement forconcrete, already efficient at very early stages of the crackingprocess. Moreover, glass fiber density is similar to concrete, whichallows a quick dispersion for very short mixing times, with minimumclumping risk and exceptionally low influence on workability.

Why Glass Fibers in Concrete?

It is widely accepted within the concrete industry that traditional concrete mixes are prone to plastic shrinkage during the setting phase and this can often lead to cracking. The addition of relatively small amounts of fiber reinforcement can effectively reduce this problem by controlling this early-age plastic shrinkage cracking. It also avoids the need for using light steel mesh for crack control with its attendant disadvantages of handling and positioning. Fiber reinforced concrete is easy and cost effective and it also enables you to produce a hardened concrete which has:

- Improved surface quality

- Greater impact resistance

- Increased durability

Why Anti-Crak® Glass Fibers in Concrete?

Anti-Crak®glassfibers are alkali resistant glass fibers, especially developed for the reinforcement of cementitious mortars and concrete mixes. They can be easily introduced into a conventional concrete mix giving millions of dispersed fibers per cubic metre of concrete, providing a highly uniform and effective reinforcement.

With its total affinity to cementitious composites, high tensile strength and modulus of elasticity, glass fibers are an ideal reinforcement for concrete, already efficient at very early stages of the cracking process. Moreover, glass fiber density is similar to concrete, which allows a quick dispersion for very short mixing times, with minimum clumping risk and exceptionally low influence on workability.

Anti-Crak®glass fibers from Owens Corning is superior in quality and performance. Besides, glass fibers out-perform polypropylene fibers in terms of quality, performance and sustainability. The following picture shows the difference between polypropylene and glass fibers in concrete. The technical details given in this website would show why more people prefer AR Glass Fibers to polypropylene.

- High modulus of elasticity for effective long-term reinforcement, even in the hardened concrete.

- excellent for early-age performance.

- A reinforcing material which does not rust nor corrode and requires no minimum cover.

- Ideal aspect ratio (i.e. relationship between fiber diameter and length) which makes them

- A fiber which is safe and easy to handle and does not protrude through the finished surface nor sink.

Following are the three main AR (Alkali Resistant) Glass Fiber Products used to strengthen and/or reinforce the concrete:

Anti-Crak® HD 12mm

Chopped Strands for Plastic Shrinkage Control

Anti-Crak HD (High Dispersion) is an engineered AR (Alkali Resistant) Glass Chopped Strand designed for mixing in concrete and all hydraulic mortars.

Anti-Crak HD fibers are typically used at low addition level to prevent cracking and improve the performance of concrete, exterior plastering, flooring, renders or other special mortar mixes.

Advantages and Benefits:

- Control and Prevention of cracking in fresh concrete

- Improves performance of concrete, flooring, renders or other mixes.

- Invisible on the finished surface

- Fibers do not protrude through the surface

- High Dispersion: 200 million filaments per KG in fiber length 12mm

- Does not corrode

- Effective at very low dosage

- Homogeneous mix

- Safe and easy to handle

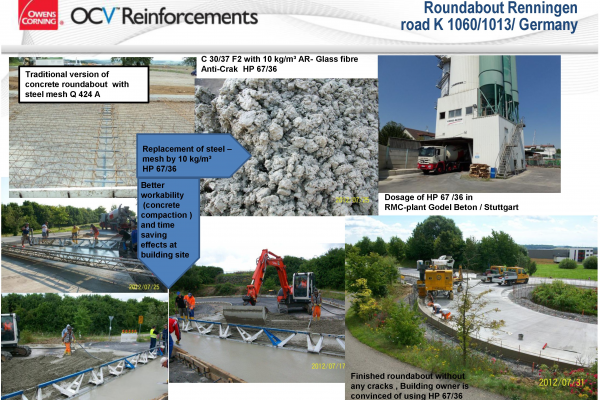

Anti-Crak®HP 67/36

Macro Glass Structural Fiber for Concrete Reinforcement

Anti-Crak®HP 67/36 is a "High Performance" Alkali Resistant Glass Macro Fiber, engineered to reinforce against plastic, thermal and drying shrinkage cracking. Anti-Crak ® HP 67/36 increases flexural strength and ductility, and adds toughness, impact and fatigue resistance to the concrete.

ProductApplication:

- For replacement of Secondary and Primary Reinforcement (welded wire reinforcement, light rebar, steel and synthetic fibers) in Residential, Commercial and Industrial slabs-on-ground, compression layers, pavements, internal roads, precast concrete, deck slabs etc.

Advantages and Benefits:

- Alkali Resistant Glass, No Corrosion

- Specific Gravity- 2.68 (equal to Concrete/ Mortar)

- High abrasion resistance

- Increase in Compressive Strength ( 13~15 %)

- Increase in Flexural Strength (13~15%)

- Increase in abrasion resistance, Decrease in Permeability

- Control & Prevention of cracking in fresh and hard concrete and mortars

- Improves mechanical properties of hardened concrete

- Fast and uniform dispersion during blending

- Does not affect concrete pumpability

- No additional water demand

- Savings in RCC cost compared to other rigid fibers - steel fiber / PP fiber.

Manufactured by: Owens Corning Composite Materials LLC

- 1 Owens Corning Parkway, Toledo, OH 43659, U.S.A.

Exclusive Distributor ( Industrial Floor Segment) :

Petroguard Canopy Systems

- 11, Asmita Garden II, Poonam Sagar Complex, Mira Road,

- Thane 401 107, Maharashtra, India

- Phone:+91 22 6529 8317

- Mobile: +91 9769244125

- E.mail:info@petroguardcanopy.com

- Website:www.petroguardcanopy.com

- Branches:Mumbai /Bangalore /Cochin /Coimbatore